Case Studies

Delivering Powerful Tech Solutions. Your project is in experienced hands. No matter what the Breadth, Complexity or Scale.

Proven Success: A Look at Integri's Impact. Integri provides a range of case studies showcasing their successful implementation of projects across various industries and highlighting the positive outcomes achieved for their clients. These case studies demonstrate Integri's ability to tackle complex challenges, deliver tailored solutions, and achieve tangible results.

Integri's past performance examples showcasing their expertise in developing and integrating software solutions for the Aerospace and Defense (A&D) industry, particularly for NAVAIR.

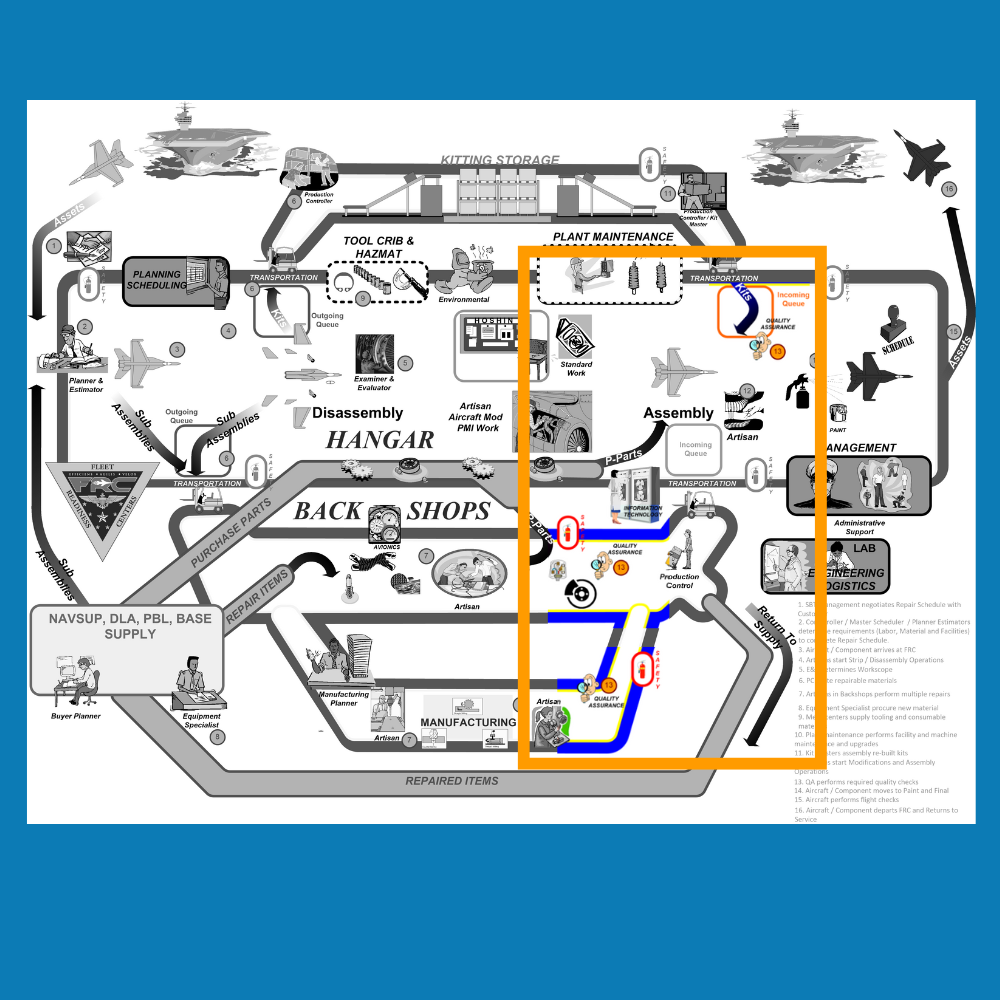

JDA Maintenance, Repair and Overhaul (MRO) is a comprehensive Commercial Off The Shelf (COTS) application for businesses engaged in project-oriented manufacturing and re-manufacturing. It provides capabilities for repair resource planning, induction processing, and re-manufacturing management for the project-oriented Aerospace and Defense (A&D) industry and government Depot-Level MRO facilities.

Integri has supported the Naval Air Systems Command (NAVAIR) NAVAIR Depot Maintenance System (NDMS) Program Management Office and has extended the capabilities of the MRO software by integration of other specialized design solutions.

Each example demonstrates Integri’s ability to analyze existing systems, identify areas for improvement, and develop or integrate tailored solutions that streamline operations, enhance data accuracy, and optimize inventory management. The examples emphasize Integri's successful collaboration with government agencies and their adherence to industry standards.

Case Studies

-

Challenge: Streamline Contract Administration

Challenge: Streamline Contract Administration with Integrated Technologies Details

Solution: Developed an application integrating SharePoint and .NET.

Results: Improved data entry, reporting, and user adoption for contract management.

-

Challenge: Streamline Budget Formulation and Execution

Challenge: Streamline budget formulation and execution.

Solution: Re-architected the outdated application to J2EE for improved functionality.

Results: Increased accessibility and improved cost control for Cost Center Managers and the Comptroller.

-

Challenge: Eliminate Reliance on Outdated Support Tools for an Automated Storage and Retrieval System

Challenge: Eliminate reliance on outdated support tools for an Automated Storage and Retrieval System (ASRS).

Solution: Conducted an engineering study to identify functionalities and migrate application into an existing MRO tool.

Results: Reduced development risk, streamlined processes, and enabled faster deployment of new features.

-

Challenge: Enhance Material Support and Resource Optimization for the Material Partnership Program

Challenge: Enhance material support and resource optimization for the Material Partnership Program.

Solution: A multi-step solution of Breadth, Complexity and Scale, encompassing all facets of the MRO operations.

Results: Streamlined inventory management and ensured parts availability for aircraft, engine, and component maintenance. Improved material readiness and visibility by ensuring accurate inventory data.

-

Challenge: Enhance Data Accuracy and Reporting for Quality Assurance (QA)

Challenge: Enhance data accuracy and reporting for quality assurance (QA).

Solution: Migrated the Quality Assurance application from Oracle Forms to J2EE for improved functionality.

Results: Increased accuracy and efficiency of QA data collection, processing, and reporting.